I know other MDs in the Group. They work in similar industrial environments as we do, which gives me access to valuable experience.

Network provides valuable knowledge

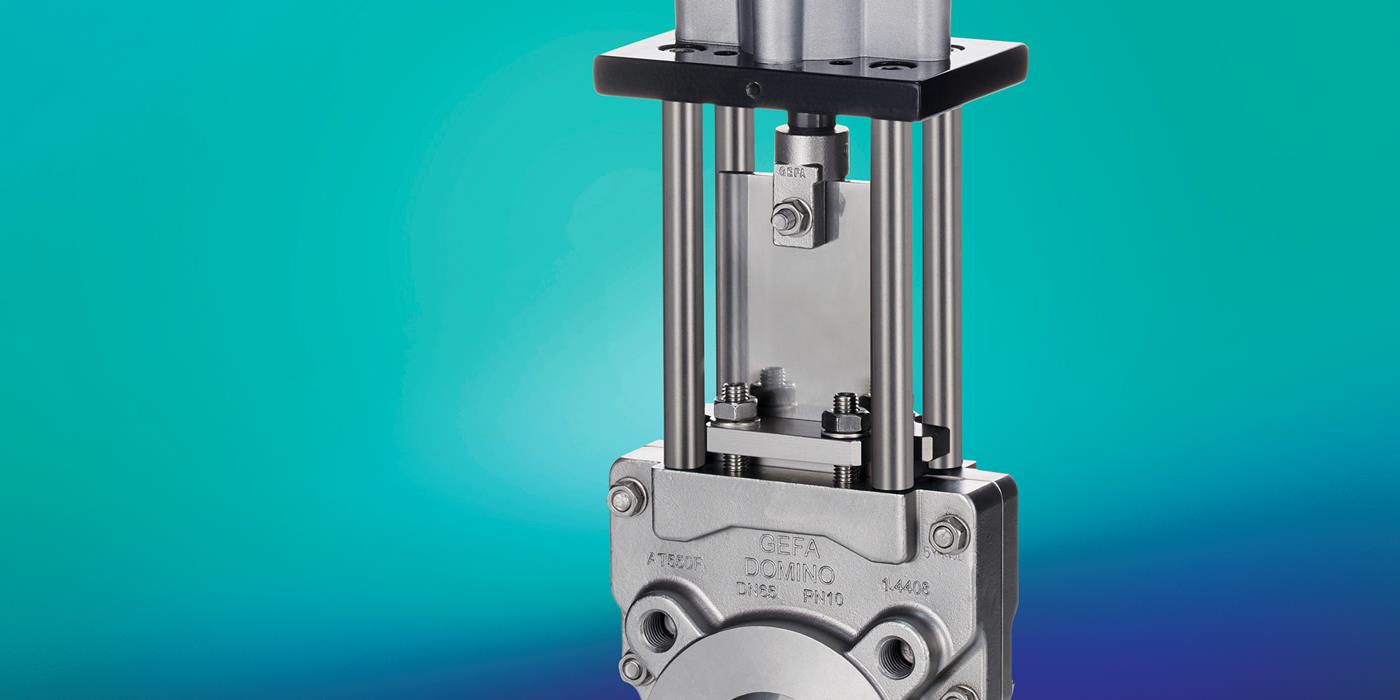

GEFA was established in 1964 as a German sales company for Gothenburg-based Gustaf Fagerberg AB. At the end of the 1970s GEFA lost several key agency agreements for the German market, and as a result the company started its own production. Initially the company made primarily standard valves, but this subsequently evolved increasingly into production of specialised products. The company's portfolio today consists to 90% of various types of valves and peripheral products. Butterfly valves are the large product category, followed by knife gate valves, ball valves and check valves.

Customers are primarily in the process industry. Major customer groups include companies working in the chemical, pharmaceutical, food and brewery industries. About 70% of sales are in the German market, but a growing share are exported. In 2009 a subsidiary was formed in China, mainly for sales, but also with a small assembly plant for products for the Chinese market.

One of Indutrade's first manufacturing companies

GEFA was acquired by Indutrade in 2001 as part of Gothenburg-based Gustaf Fagerberg AB and was thereby one of the first manufacturing companies to become part of Indutrade, which until then had been primarily focused on trade.

“Indutrade’s decentralised business model gives us freedom to develop the business based on our own conditions,” says Gerd.

Indutrade’s decentralised business model gives us freedom to develop the business based on our own conditions

At the same time, he sees major benefits in the extensive network that he has access to in Indutrade.

“I know most of the other MDs in the Group,” he says. “They work in similar industrial environments as we do, which gives me access to valuable knowledge and experience.”

Concrete example of knowledge sharing

A concrete example of this is the inspiration that GEFA gained from HP Valves, another of the Group’s manufacturing companies, to implement a continuous improvement programme (CIP). The programme has now been in use for two years and has contributed to many positive changes.

“The CIP has helped us solve a number of specific problems at the same time that it has generally enabled us to work in a more structured manner than previously,” says Gerd.

Ambition to become more international

The company's future plans call for continued development of customised special solutions, and the design department was recently reinforced for this purpose. In addition, investments in machinery are planned to increase flexibility and automation, and to drive the digitalisation process. “We also have the ambition to become more international,” Gerd adds. “There is a long list of countries in which we have very small sales, or none at all.”